Welcome to VENUS ENTERPRISES (INDIA)

ABOUT US:

We have pleasure to introduce ourselves as a reputed manufacturer of engineering items for Steel Industry, Tyre Industry, Paper Mills, Sugar Industry, Electronic Equipment Manufacturing unit, etc.

- The company was started in 1993 with modest operations, today our products are widely accepted throughout India in Paper/Steel/Tyre/Sugar Industries respectively.

- We have developed and supplied some of the critical jobs as per the buyers requirement and acclaimed customer appreciations for our quality work. With the team of skilled and hard working members we have been able to carve a niche for ourselves within our buyers.

- Mr .Anil Kumar Singhal established the company as his sole venture in year 1993, and started manufacturing of high quality mechanical items used in tyre industry. Further he entered in the field of supplying mechanical items used in Steel plant and Paper mills.

- Under the aegis of the mentor, the company carved a niche in the industry and at present, Mr. Anil Singhal, Mr. Gaurav Singhal and Mr. Vikram Singh manages the company. Their dynamic leadership and sharp business acumen has been instrumental in the further growth.

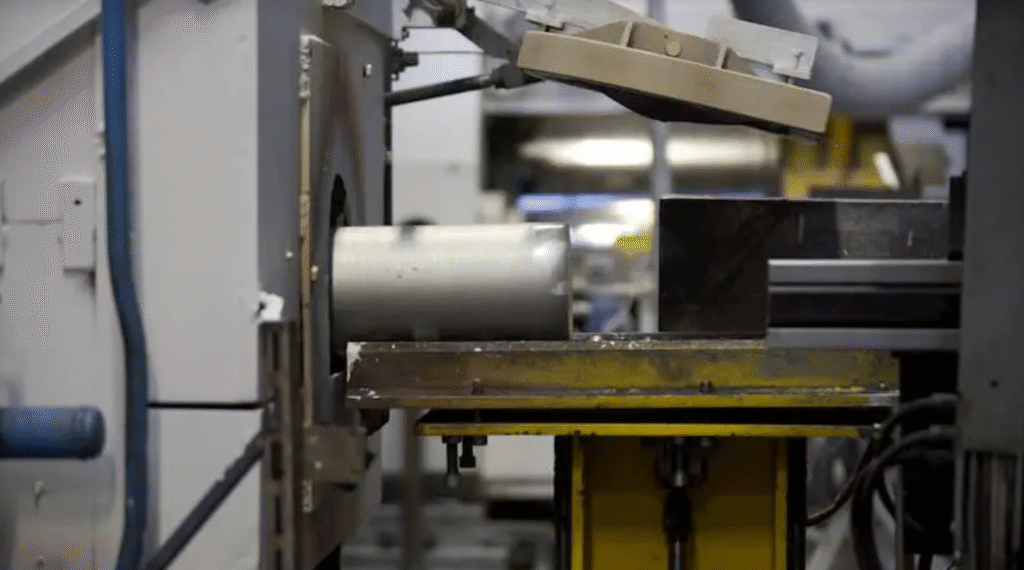

Milling

Milling is a subtractive manufacturing process involving rotating cutting tools that remove material from a solid block to form intricate parts. A staple of tooling design, it is particularly used to create cavities, slots, and contours with tight tolerances in steel or nickel alloys, as well as other hard materials.

Tooling in manufacturing supports both prototype tooling and mass production tooling, thanks to its precision and flexibility. Although it is slower than other methods and is geometry-constrained within close quarters, it’s well-suited to high quality tooling design, along with dimensional accuracy in various tooling materials.

Milling

Milling is a subtractive manufacturing process involving rotating cutting tools that remove material from a solid block to form intricate parts. A staple of tooling design, it is particularly used to create cavities, slots, and contours with tight tolerances in steel or nickel alloys, as well as other hard materials.

Tooling in manufacturing supports both prototype tooling and mass production tooling, thanks to its precision and flexibility. Although it is slower than other methods and is geometry-constrained within close quarters, it’s well-suited to high quality tooling design, along with dimensional accuracy in various tooling materials.

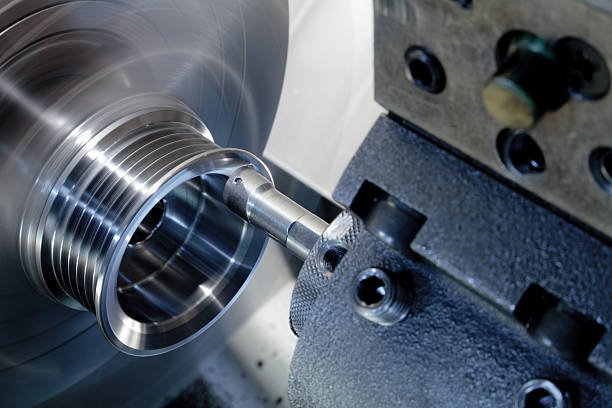

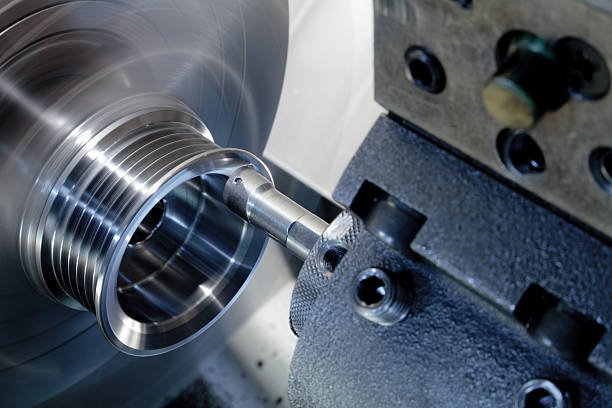

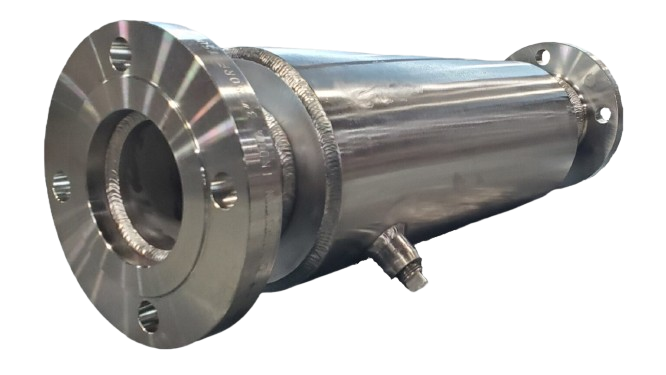

Turning

This is a manufacturing process that uses rotating workpieces and a fixed cutting tool to create cylindrical-shaped parts. It is usually used on a lathe and is the perfect tool for creating symmetrical components with tight tolerances, particularly for hard tooling applications.

When it comes to tooling in manufacturing, turning is vital for producing cores, pins, and shafts used in injection molding and die casting. It’s a quick and efficient way for high volume production, although it is limited to round or tubular geometries, thus making it less ideal for complex profiles or soft tooling designs.

Turning

This is a manufacturing process that uses rotating workpieces and a fixed cutting tool to create cylindrical-shaped parts. It is usually used on a lathe and is the perfect tool for creating symmetrical components with tight tolerances, particularly for hard tooling applications.

When it comes to tooling in manufacturing, turning is vital for producing cores, pins, and shafts used in injection molding and die casting. It’s a quick and efficient way for high volume production, although it is limited to round or tubular geometries, thus making it less ideal for complex profiles or soft tooling designs.

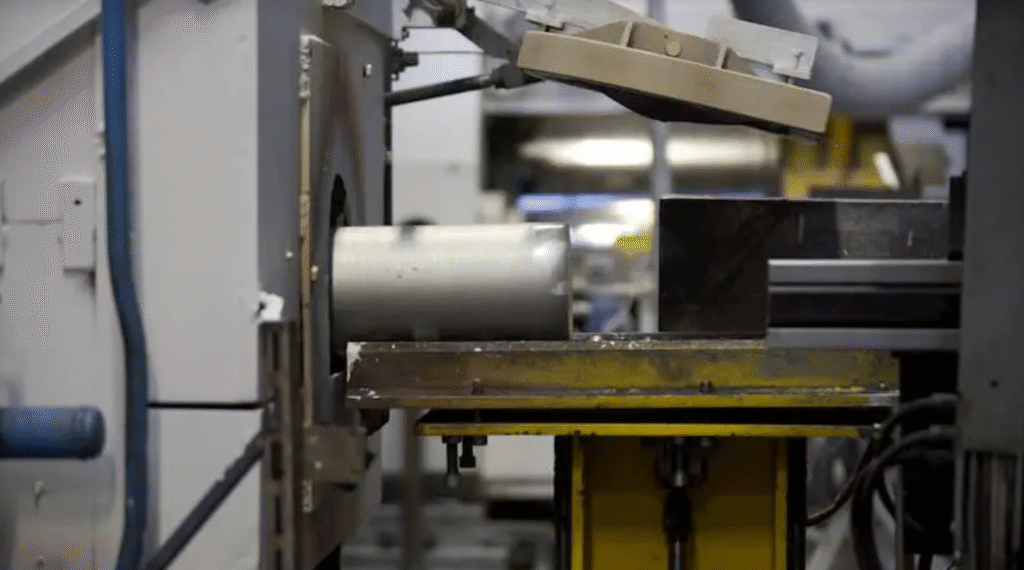

Grinding

This is a finishing tooling process that makes use of an abrasive wheel to remove small amounts of material for a smoother and accurate surface. It is particularly helpful in refining tooling components that require high precision and tight tolerances.

Grinding tends to be the final step of the tooling design and allows for dimensional accuracy and surface finish for molds, dies, and other production tooling. Although it’s an incredible tool for high quality tooling, it lacks the ability to remove large amounts of materials, and can increase tooling cost because of time and specialized equipment.

Grinding

This is a finishing tooling process that makes use of an abrasive wheel to remove small amounts of material for a smoother and accurate surface. It is particularly helpful in refining tooling components that require high precision and tight tolerances.

Grinding tends to be the final step of the tooling design and allows for dimensional accuracy and surface finish for molds, dies, and other production tooling. Although it’s an incredible tool for high quality tooling, it lacks the ability to remove large amounts of materials, and can increase tooling cost because of time and specialized equipment.

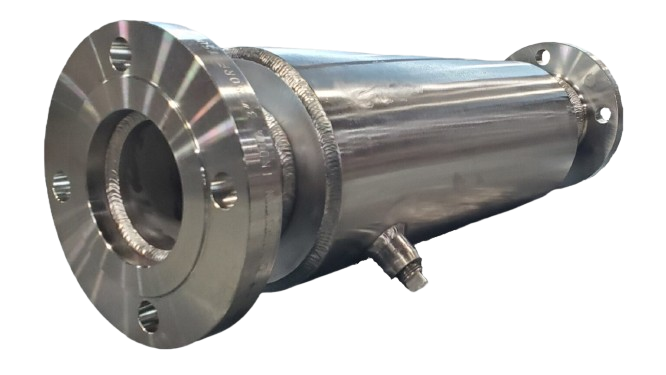

METAL Extrusions

Metal extrusion is a forming process in which we force a metal (either hot or cold) through a die. This imparts the die shape to the extruded metal as it passes through the cavity. The material emerging from the die is known as “extrudate”.

The metal endures compressive and shear stress to achieve the die shape. The nature of these forces and the elevated temperatures enable us to form materials with otherwise brittle properties using this process.

Besides metals, nonmetals such as ceramic, plastic, clay, concrete, polymers, etc. are also suitable for extrusion.

METAL Extrusions

Metal extrusion is a forming process in which we force a metal (either hot or cold) through a die. This imparts the die shape to the extruded metal as it passes through the cavity. The material emerging from the die is known as “extrudate”.

The metal endures compressive and shear stress to achieve the die shape. The nature of these forces and the elevated temperatures enable us to form materials with otherwise brittle properties using this process.

Besides metals, nonmetals such as ceramic, plastic, clay, concrete, polymers, etc. are also suitable for extrusion.

Best solution for

Customizing your

Products

Avail a comprehensive range of Steel Parts,

Auto Components, etc for different industrial applications.

OUR Specilization

RANGE OF PRODUCTS

Tool Design & Manufacturing

Make in India

In House Tools customization

Customers we have served

Best solution for

Customizing your

Products

Avail a comprehensive range of Steel Parts,

Auto Components, etc for different industrial applications.